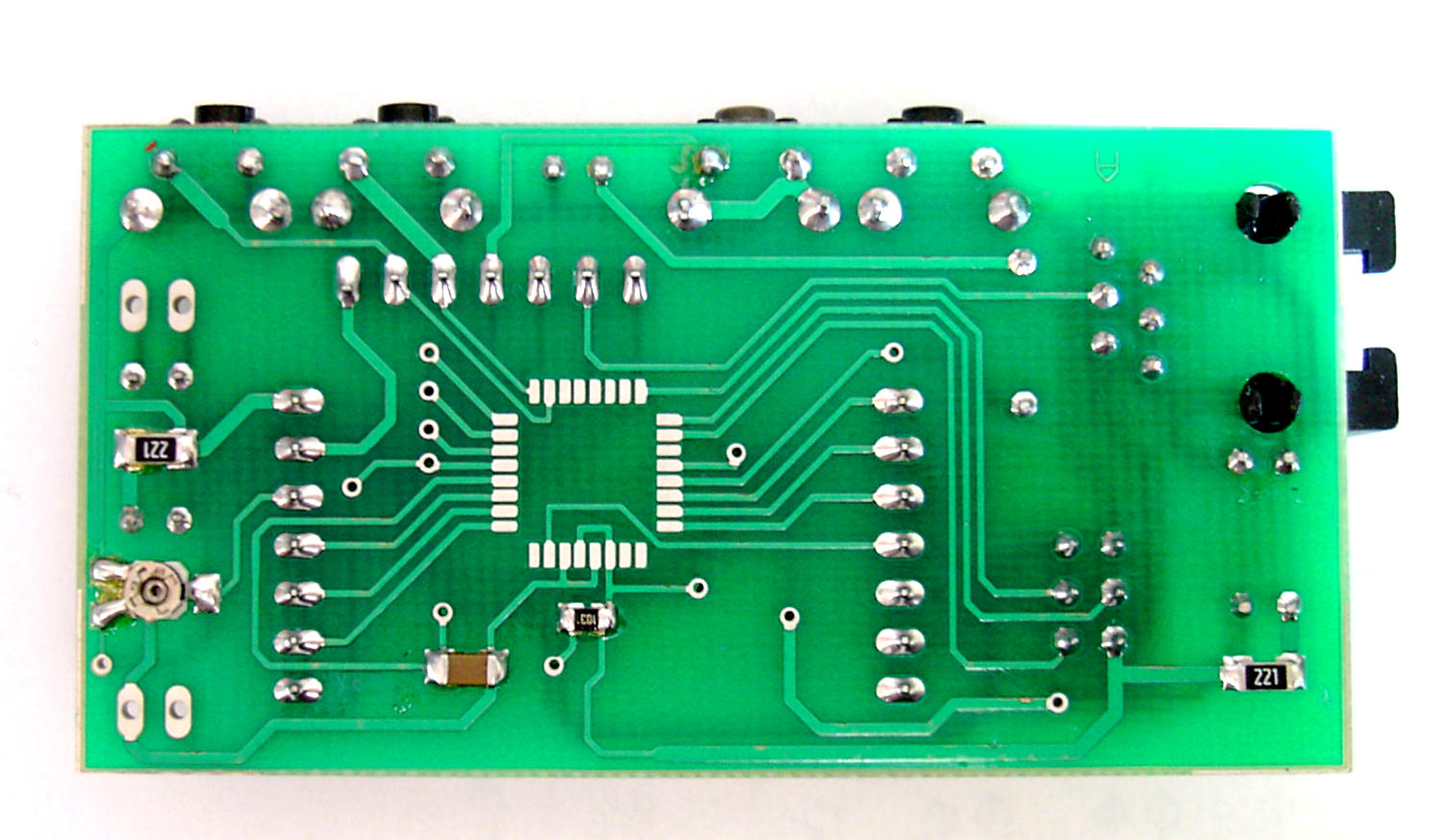

pcb board

A printed circuit board (abbr. DPS, English printed circuit board, abbreviated PCB; other names see below) is a board made of a non-conductive substrate, on which conductive connections are created based on the wiring diagram of a specific circuit, which connect individual electronic elements. It serves as a supporting and structural element of electronic circuits composed of several separate electronic elements.

Names

In total, the following names occur:

with "circuit board" in title: printed circuit board, printed circuit board, printed circuit board, printed circuit board, printed circuit board, printed circuit board

in the term "printed joint" in the title: printed circuit board printed circuit board printed circuit board

with "printed circuit" in the title: printed circuit board, printed circuit board, printed circuit board, printed circuit board

with "printed circuit board" in the title: printed circuit board, printed circuit board, printed circuit board

The names printed circuit board and printed circuit board seem to be the most common.

Types

According to the number of layers, PCBs are divided into single-layer, double-layer (double-sided) and multi-layer. Single-layer PCBs are the simplest because they do not need conductive connections between individual layers. Double-layer PCBs contain joints on both sides of the carrier material, the connections between them are formed by forged holes (so-called vias). Multi-layer PCBs contain conductive layers inside the material as well and are produced by connecting several single- and double-layer PCBs with insulating intermediate layers. Although more technologically demanding, multi-layer PCBs allow simpler design of complex electronic circuits and better circuit properties (e.g. reduced interference).

History of DPS development

The inventor of the printed circuit board was the Austrian engineer Paul Eisler, who made it as part of a radio receiver while working in England. Around 1943, this technology began to be used on a large scale in the US to produce rugged radios used in World War II. After the war, in 1948, the USA published the invention of DPS for commercial use. However, printed circuit boards were not commonplace in consumer electronics until the 1950s, when the United States Army developed a process for their automatic assembly. The invention of the PCB was preceded by a technique of a similar nature, invented by the British electrical engineer John Adolph Sargrove (originally surnamed Szabadi). It was metal sprayed onto Bakelite insulating board. The equipment using Sargrove's technology, originally called Electronic Circuit Making Equipment - ECME (translated as equipment for the production of electronic circuits), made it possible to produce 3 radios per minute.

Construction

Conductive layers of the PCB are standardly made of a thin copper foil (several tens of μm thick). The insulating layers are a combination of laminate and epoxy resin (usually 1.5 mm). Printed circuit boards are produced in three standard colors: green, blue and red. Depending on the requirements of the electronic circuit, it is possible to choose from several dielectric materials with different insulating properties. Examples of such materials are: polytetrafluoroethylene (Teflon), cotton paper with phenol FR-2, cotton paper with epoxy FR-3, glass fiber cloth with epoxy FR-5 and polyester FR-6. Probably the most important property of DPS is thermal expansion, which determines their dimensional stability. DPS made on the basis of glass fibers have probably the smallest thermal expansion and therefore the best properties.

Nowadays, PCBs also contain simple electronic devices. With the current mass production of printed circuit boards, their price is very low and their reliability is more than satisfactory. However, the design and production of the PCB itself is not a cheap matter, but by using appropriate technologies, the manufacturer can achieve a negligible production price considering the price of the electronic components used. PCBs have countless advantages over constructions with wire connections or point-to-point constructions, despite the complexity of PCB production. The main reason for using DPS is also the possibility of fully automating the production of electronic devices. Standards published by the IPC organization are established for the needs of quality control and PCB assembly.

Theme design

The motif of the conductive paths is usually created by specialized computer CAD programs, based on a drawing of an electrical circuit drawn usually in the same program. The motif is then transferred to a transparent foil, which serves as a template for PCB production.

Processing

In the production of a double-sided PCB, the board is first drilled on a coordinate-controlled drill (CNC) based on the designed motif, then a thin layer of metal is applied to the drilled holes by a chemical method, which is then galvanically (electrochemically) thickened.

The method of production of conductive connections on a printed circuit board mainly depends on whether it is a matter of their mass production, or whether they are to be used for the construction of a single device, e.g. prototype or amateur product.

Initially, we can divide production technologies into two basic ones. The first is the application (printing) of conductive connections on the insulating layer. The second method is the removal of part of a continuous layer of thin copper foil vaporized on an insulating substrate. Nowadays, the second of the mentioned methods is more often used. The motif of the tracks is transferred to the PCB by photolithography: the PCB is covered with photoresist, it is exposed to UV light through

foil with a motif, while of course paying attention to the overlap with the drilled holes and the overlap of both sides, the photoresist is induced and then the exposed parts of the copper foil are etched away. After the photoresist remains have been removed, the conductive copper surfaces are plated (tin or gold) to prevent oxidation of the copper, which would make subsequent assembly (soldering) of the components difficult or impossible. It is then applied and shaped by the so-called a non-soldering mask that covers the places that will not be soldered and prevents the solder from reaching these places. Finally, the PCB can be screen-printed with help texts and drawings to aid in board placement and circuit repair.

Another option for creating a mask is screen printing, which uses durable inks to protect the desired conductive connections from etching. Screen printing can also be used in the method of applying conductive joints to a flexible insulating base, which is mainly used in the production of flexible PCBs or movable leads.

Another method is milling, by which we remove the unnecessary part of the copper foil applied to the insulating base. With this production method, there is no need to cover the board with a mask. With suitable software, we create a circuit board pattern (mask) and with the help of a milling device similar to a plotter (CNC device), unnecessary copper is systematically milled from the board.

Peculiarities

Flexible PCBs do not have a flexible but rigid plastic film as a carrier layer. They are often used as a movable feed (e.g. to a movable print head of a computer printer) or in space-limited devices (where they can be shaped even into a small volume).

For high-frequency and microwave devices, PCBs are made from materials with lower dielectric losses at high frequencies, e.g. Teflon or synthetic corundum (Al2O3).

In very cheap consumer electronics devices, the base material is usually a laminate containing paper instead of glass fabric, used exclusively for single-sided PCBs.